Vacuum, as opposite to compressed air, today is also getting more or more used in

applications like packaging in foodstuff or pharmaceutical industry, parts assembly of

electronics, LCD panel handling or glass transferring in automotive, metal coating or surface treatment, etc.

But what exactly vacuum is? And how it is defined?

First a basic knowledge of physics to know,

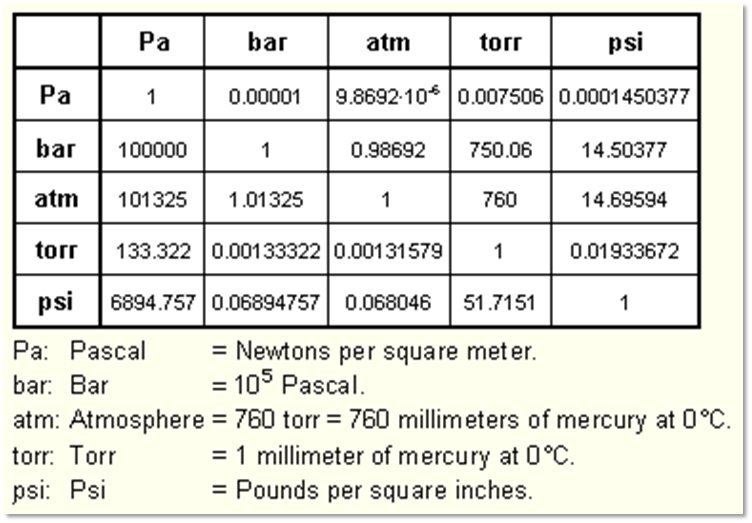

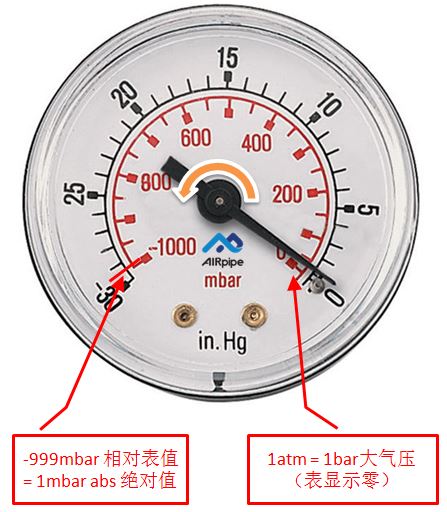

a standard atmosphere pressure = 1atm = 760 mmHg = 1.01325 x 10^5Pa = 1.01325bar,

other units see below table.

Too much? Ok, just easily to understand the ground level now you stand there is 1atm pressure,

the reading of gauge you see is zero relatively, but absolute pressure actually is 1bar

around you since air also has weight. (easy? now feeling pressure on you head?)

Now, vacuum is just the opposite direction, when air being pumped out the pressure

will drop, theoretically it will reach down to -1bar ultimately, but it won't get there

while just close to it, and the gap to the -1bar is what we call the absolute vacuum.

AIRpipe sealing structure is a constant belt contact around the pipe, it's wider than

a normal o-ring, and together with its superior longevity and durability, the sealing

performance for vacuum is highly secured same as its compressed air.

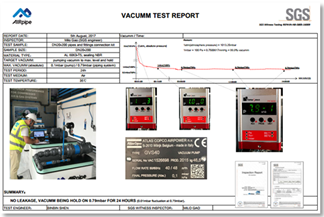

AIRpipe guarantees 1mbar absolute, equals to 100Pa = 99.9%, this reaches most of the

vacuum applications request. (test result data is 0.79mbar / 99.92%, better than 1mbar)

Compared with compressed air system, vacuum is more demanding on the sealing

performance and cleanness of the pipe, since a tiny leakage will largely drop down

the system vacuum level, and rusts and dusts in the pipe will create heavy load to

vacuum pump downstream, that all about of waste money, so to install a good

quality pipe system is same important as a good pump.

AIRpipe, Advancing Compressed Air System, same on VACUUM.