In today's growing emphasis on environmental protection, new energy vehicle is becoming

more and more popular, because of it's eco-friendly, saving cost, low noise and energy

saving. Our country and local government provide a large support on promoting new energy,

it has wide prospects for development.

Compressed air is necessary in the manufacture of new energy vehicle:

1. Welding shop: the protection air of welding, plasma cutter;

2. Painting shop: painting (It needs the compressed air without silicon, copper, oil ····

3. Assembly shop: pneumatic tool, pneumatic equipment, etc.

4. Finished inspection shop: pneumatic tool, pneumatic equipment, etc.

······

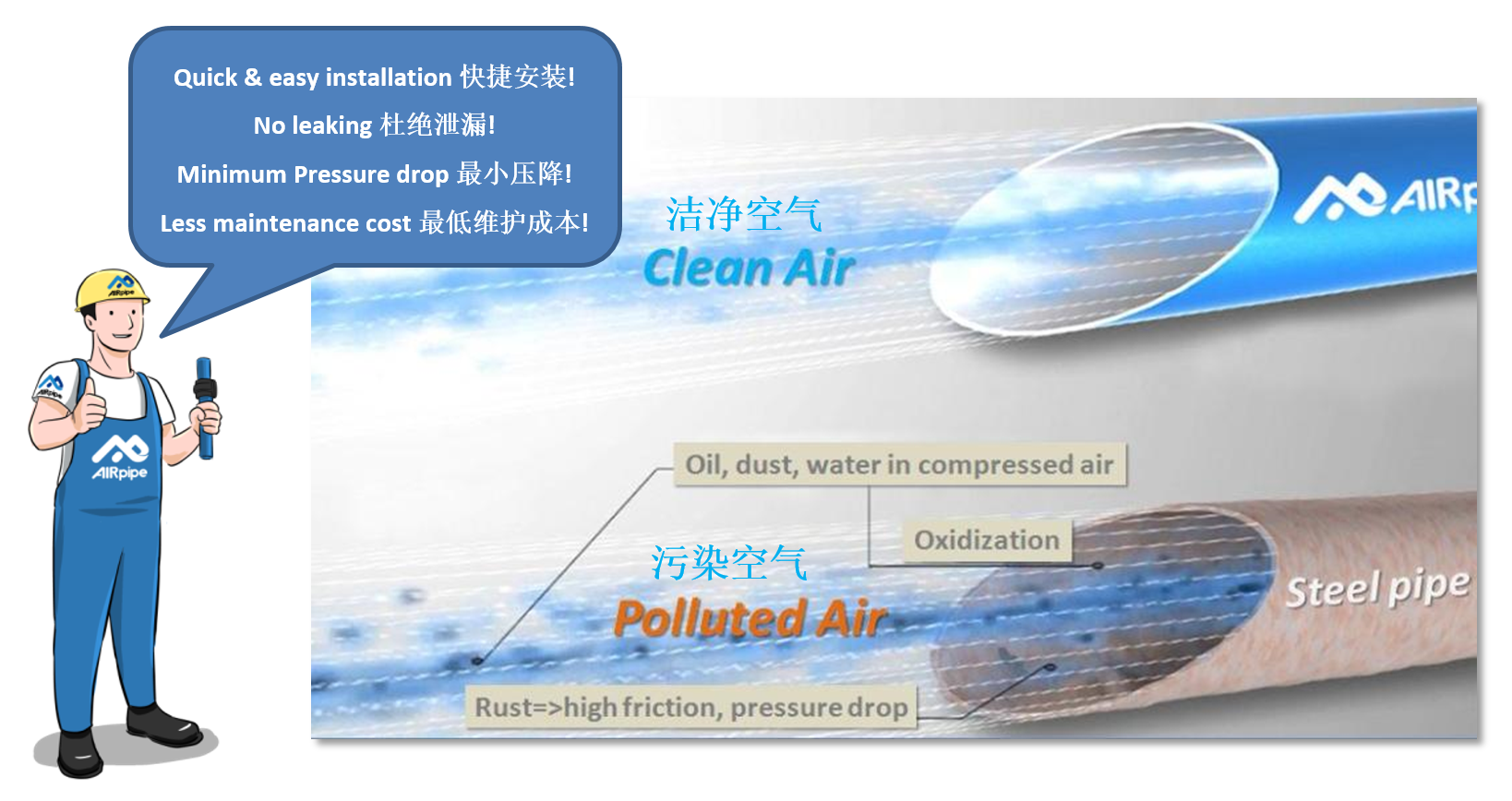

In traditional market, carbon steel pipe is widely used, but for new energy vehicle industry,

whom pursue high efficiency and energy saving, Corrosion, leakage, pressure drop ······

is no longer reach it's requirements like clean, energy saving. An AIRpipe's new energy

vehicle customer feedback: “The carbon steel pipe had long-term storage of water in the

pipeline, causing rust and corrosive impurities in the it. The terminal pressure loss is

serious and the compressor is always in the state of full load loading''.

After transform the AIRpipe, have obvious advantages: ‘'The pipe

construction timescale is shortened by more than half, the installation is

simple and convenient, which greatly reduces the post-maintenance costs

and human resources. The loss of terminal pressure drop and the air

compressor load is significantly reduced, energy consumption is greatly

reduced by 10%. The pipe eliminates the problem of long-term wet

corrosion, and no impurities flow with the airflow to the terminal to damage

the pneumatic components.

With our own patent R&D of advanced connection technology, strict product quality

requirements, perfect service system, AIRpipe is widely used in various industries, and always

leading the healthy development of the solutions for compressed air and fluids distributions.