AIRpipe specialize in solutions for compressed air and fluids distribution. In addition

to main compressed air applications, it is being more and more used in vacuum

system due to booming market of electronic, pharmaceutical & food industry.

Electronic semi-conductor

Optoelectronic backlight module

Machinery

New energy

Package

Food & Medical

......

Above industries are involved with vacuum system. According to the characteristics of the gas

materials, operating pressure & temperature, an appropriate piping system are selected.

Traditional carbon steel pipe thread joint has poor airtightness and easy to corrode. The cost

of stainless steel welded pipe is high and the installation time is consumed. Aluminum pipe

had obvious advantages in cleanliness and installation man-hours. So it has been

increasingly recognized by users in recent years.

The engineer of Energy Facilities Department from a Lighting Technology Company said “Our

workshop is a constant temperature and dust-free packaging workshop. The vacuum is mainly

supply the automatic packaging robots in the production line, a great concerns about the vacuum

pipes is the leakage, and AIRpipe vacuum pipeline is very well sealed without any leakage, very

convenient to assemble and disassemble.”

The PD product manager from an electric technology co., Ltd. said “We installed your company's

aluminum compressed air pipe system before, and we are satisfied with it's clean air quality

and great sealing effect. So when we are ready to transform the old vacuum pipeline, AIRpipe is

our first choice. The vacuum of our factory is applied to suckers for the adsorption of electronic

products. Our products have a high degree of cleanliness. Therefore, the requirements for vacuum

piping and vacuum pumps are also very high, the cleanliness of pipeline will also help to extend the

service life of vacuum pumps.”

AIRpipe sealing structure is a constant belt contact around the pipe, it's wider

than a normal o-ring, and together with its superior longevity and durability, the

sealing performance for vacuum is highly secured same as its compressed air.

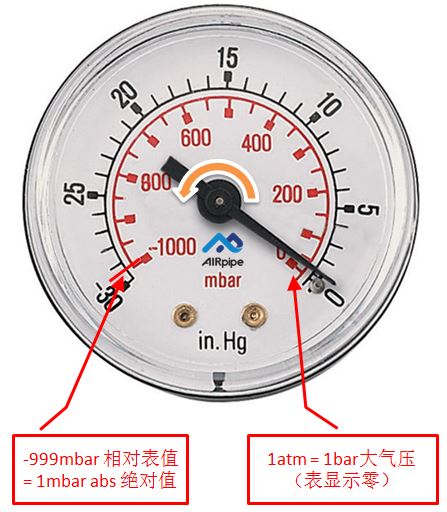

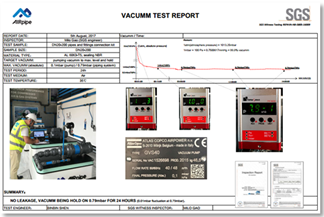

AIRpipe guarantees 1mbar absolute, equals to 100Pa = 99.9% = 0.76mmHg, this

reaches most of the vacuum applications request. (test result data is 0.79mbar /

99.92% / 0.6mmHg, better than 1mbar)

Compared with compressed air system, vacuum is more demanding on the sealing

performance and cleanness of the pipe, since a tiny leakage will largely drop down

the system vacuum level, and rusts and dusts in the pipe will create heavy load to

vacuum pump downstream, that all about of waste money, so to install a good

quality pipe system is same important as a good pump.

AIRpipe, Advancing Compressed Air System, same on VACUUM.