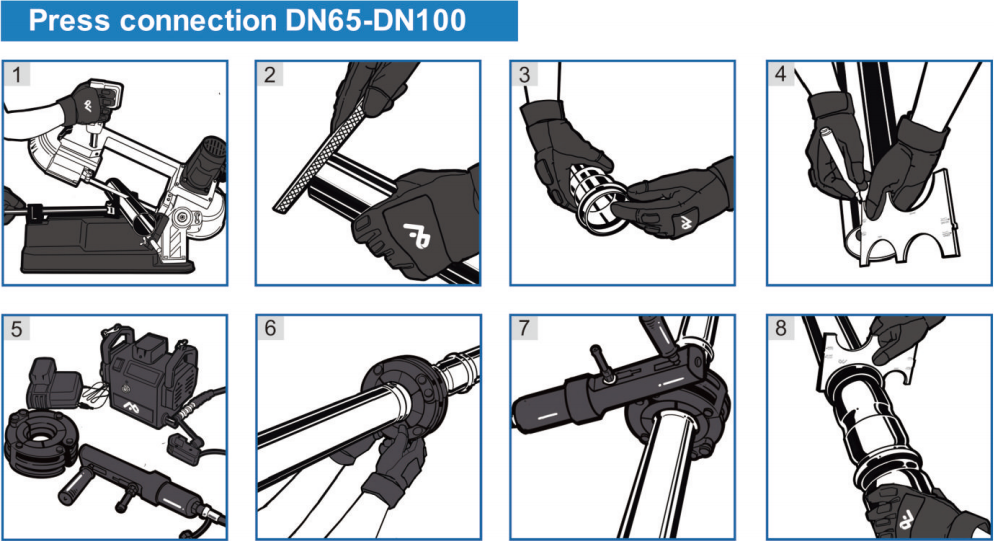

1. Use pipe cutter to cut the pipe at right angles.

2. Deburr inside and outside of pipe.

3. Check the seal is proper fit in the fittings.

4. Mark the correct pipe insertion depth, depth markings should be visible after the installation is completed.

5. Installation tools: press jaws (up and down type), cylinder base, hydraulic electric pump, etc.

6. Before pressing, install the oil hose and the press jaws (up and down type), double check.

7. Keep jaw and pipe relative vertical, press the electric pump switch, press the parts until the upper and lower two jaw head plane gap closed.

8. After the pressing, use the gauge to check whether pressing is in place

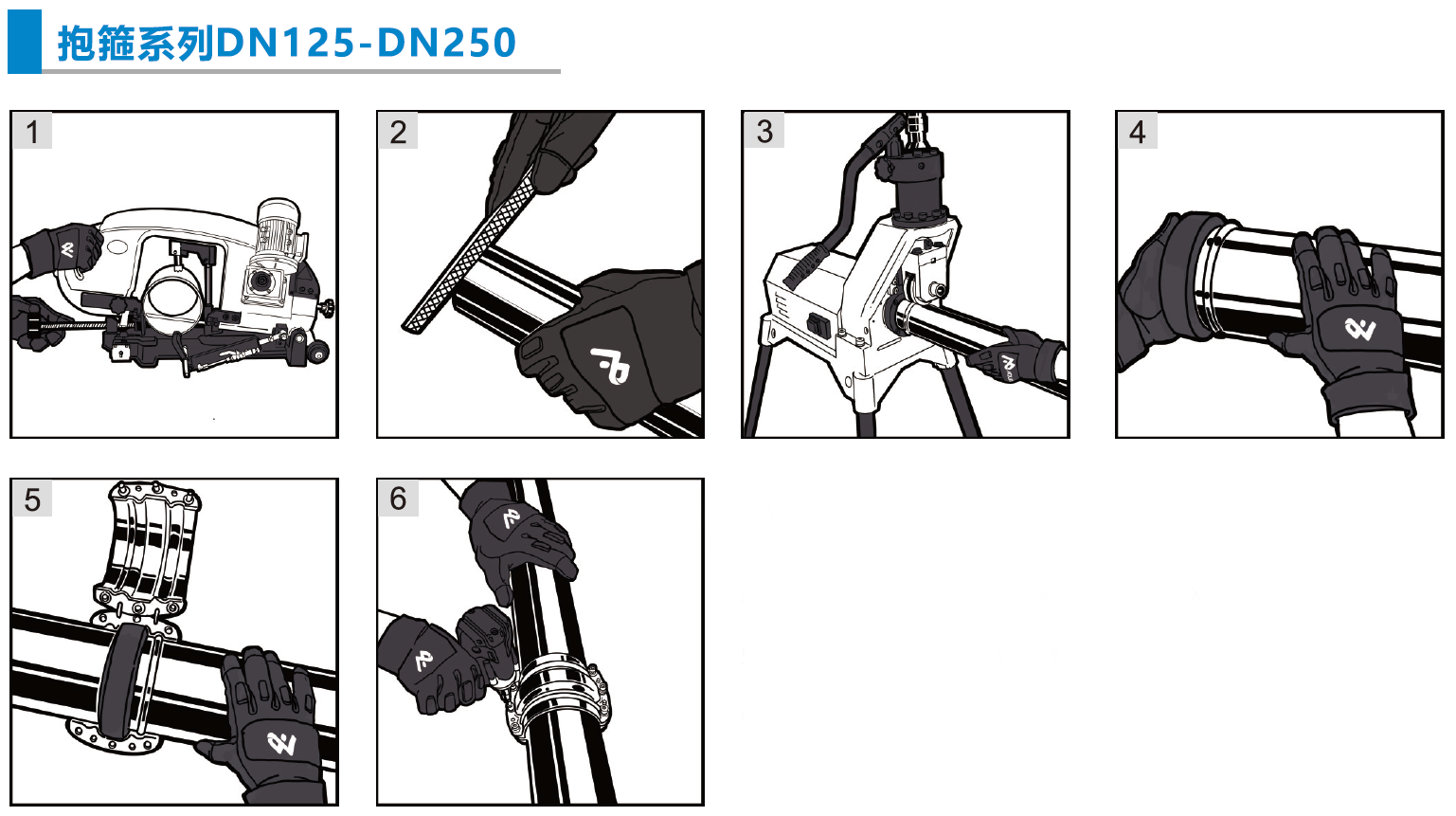

1. Use pipe cutter to cut the pipe at right angles.

2.Deburr inside and outside of pipe.

3. Check the seal is proper fit in the fittings.

4. Mark the correct pipe insertion depth, depth markings should be visible after the installation is completed.

5. Installation tools: press jaws (up and down type), cylinder base, hydraulic electric pump, etc.

6. The ring jaw is installed and locked in accordance with the convex lug of the fitting to prevent unbuckling.

7. Align the cylinder clamp base with the ring jaw connection and press the oil pump switch until the ring jaw plane gap is closed.

8. After pressing, use the gauge to check whether pressing is in place.

1. Use pipe cutter to cut the pipe at right angles.

2.Deburr inside and outside of pipe.

3. Use Lugging machine to lug the pipe, proper lugs height are request. (AQUApipe's pipes from factory are supplied with lugs at both end).

4. Open the clamshell and insert pipe into the seal to 2cm-3cm on each side.

5. Position the clamshell over the sealing, ensuring the lugs align with the grooves.

6. Flush the two clamshells together, respecting the max torque.